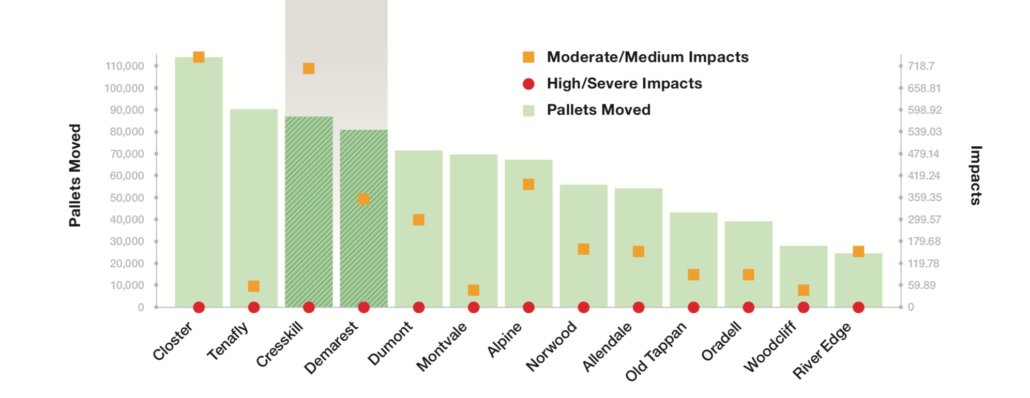

- Pallets moved to severe forklift impacts (which have a high correlation to damage) and to medium forklift impacts (an indicator of excess wear and tear over time)

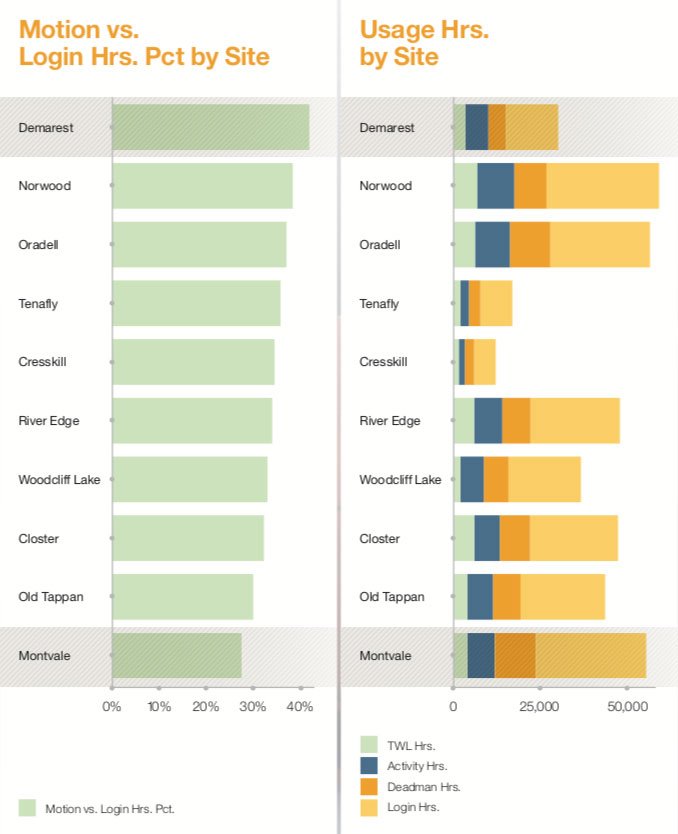

- Vehicle motion time to operator login time to Kronos® shift time

Also significantly, Powerfleet IQ enabled different standards to be set for different vehicle types, and accounted for drivers who operated different types of vehicles in same shift or day.

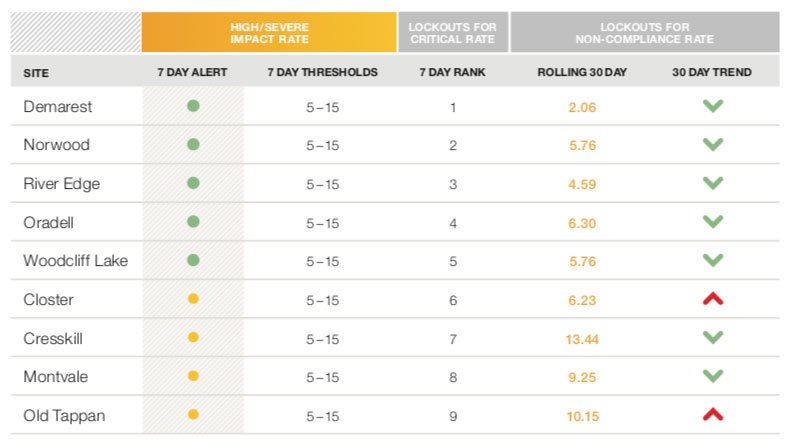

Based on these benchmark ratios, the Company set up multiple KPI scorecards for different stakeholders: individual drivers (with daily, weekly, and monthly metrics); supervisors (focused on all drivers each shift); warehouse managers (with a view of the entire facility); and corporate management (with stack-ranking of all sites in a single view).

This data hierarchy enabled a rapid, logical flow of information and decisions. Corporate management identified high- and low-performing sites. Facility managers saw where they ranked compared to other sites, and where they stood in relation to the target benchmarks. Line supervisors drilled down to understand which forklift operators were high achievers—and which needed refresher training. And forklift operators could see in black-and-white where they stood.

In the end, the food & beverage Company was able to drive much safer lift truck operations while maintaining high material velocity through its distribution system. The result was an 85% reduction in forklift damage costs with 100% achievement of target pallet moves.