The era of so-called “nuclear verdicts” began with the McDonald’s coffee case in 1994. After purchasing a coffee, a 79-year-old woman tried to hold the cup between her knees while removing the lid and spilled it on herself. The case went to court and a jury awarded her $2.7 million in punitive damages from McDonald’s callous conduct.

Multimillion dollar awards have since become alarmingly commonplace. For example, in 2012, a drive shaft broke off of a commercial truck and killed the driver of a nearby passenger car. A jury initially handed down a record verdict of $281.6 million, although that was reduced in the court of appeals to $105.2 million before being settled for an undisclosed amount.

Let’s take a look at the rise in so-called nuclear verdicts of more than $10 million and how to protect your drivers and business from them.

Nuclear verdicts have become increasingly common, making it ever more important to protect your drivers and business from liability. Share on XNuclear Verdicts & the Need for Reform

Large verdicts against trucking fleets have been increasing dramatically in both number and size, according to the American Transportation Research Institute. When analyzing case data between 2006 and 2019, the organization found that there were nearly 300 awards worth over $1 million in the past five years compared to just 26 during the first five years.

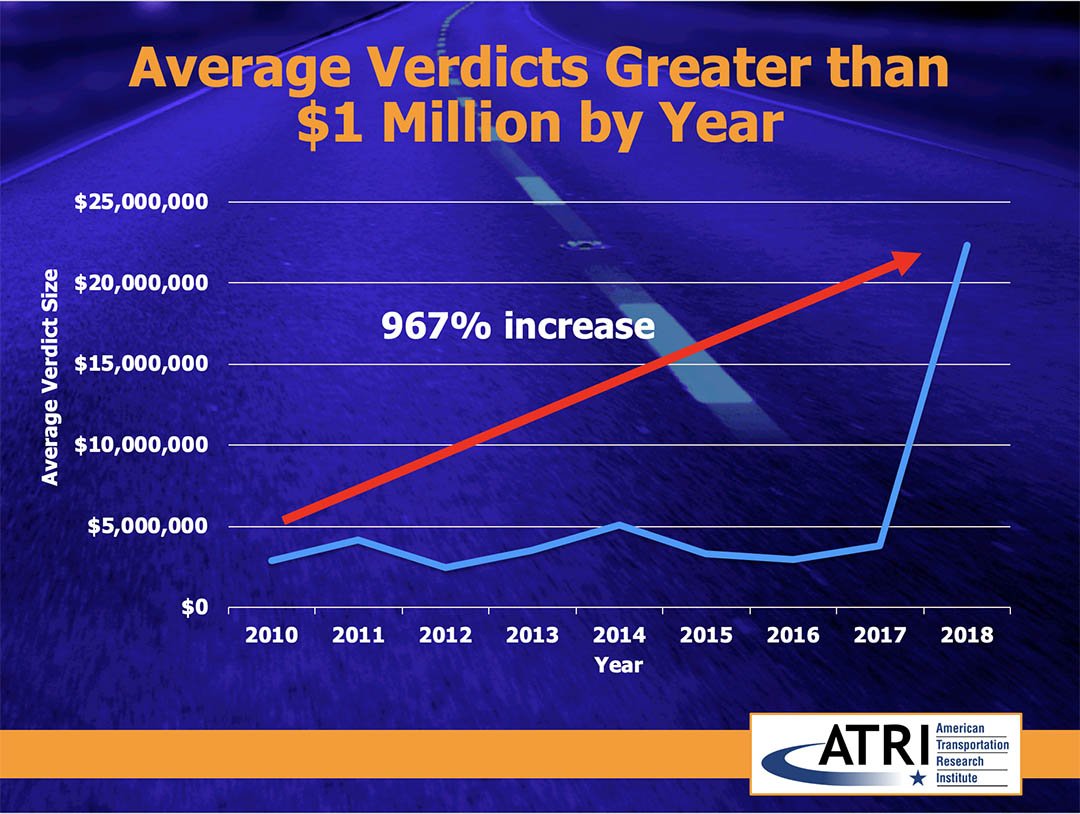

The average verdict size also rose 51.7% per year between 2010 and 2018 due to so-called nuclear verdicts, or awards for over $10 million, that often exist on tenuous legal grounds. For example, in 2011, $40 million was awarded to victims of a trucking accident after plaintiffs argued that they lost $30 million in future earnings based on an un-started business venture.

Average verdicts are on the rise. Source: ATRI

Nuclear verdicts are enough to put many small operators out of business, but they also increase costs for the wider trucking industry. For example, at least one motor carrier publicly reported an increase in a single year’s insurance rates of more than 100%—from $340,000 per year to $700,000 per year, pushing it out of business and putting 50 employees out of work.

The trucking industry—along with insurers across many other industries—have called for tort reforms to address these nuclear verdicts, citing “social inflation” like rising insurance costs for everyone. While trucking companies and drivers should be held accountable for wrongdoing, ATRI and other industry groups advocate for preventing money-grabs from trial lawyers.

Training & Documentation Best Practices

Everyone wants to prevent accidents and other safety incidents on the road. The best starting point is implementing the right training procedures to maximize driver safety. If an incident does occur, accurate and up-to-date documentation is critical to prove that the company did all that it reasonably could to prevent the accident.

There are five key risk factors:

- Driver Fatigue

- Distracted Driving

- Driving Under the Influence

- Lack of Equipment Maintenance

- Inexperienced Drivers

Training and documentation efforts should focus on minimizing these risks. For example, accurate Hours-of-Service logs can help prove that companies weren’t pushing drivers too far and causing driver fatigue. Companies should implement documented procedures to help minimize these risks and ensure that there’s a paper trail in place at all times.

All of these policies should be articulated within a written Accident Prevention Plan that’s provided to every driver. The plan should include safety training requirements, safety meet details, red flags, hours of operations policies, safety equipment checks, drug testing policies, accident investigation programs, post-accident retraining and driver recognition programs.

Some best practices to consider include:

- Proactive Maintenance: Trucking companies should log engine hours and proactively maintain engines and trailer parts to minimize the odds of an on-the-road breakdown. In addition, driver spot checks should be a requirement before getting on the road.

- Ongoing Safety Training: Trucking companies should have documented training in place that occurs at hiring, as well as on an ongoing basis. If a safety incident occurs, there should be a retraining policy and disciplinary measures.

- Recognition Programs: Safe driving recognition programs should reward drivers that avoid accidents or citations with an additional cent per mile or other tangible and meaningful cash or product-based rewards.

Using Technology to Enhance Compliance

All trucking companies are aware of Hours-of-Service regulations and common-sense rules, but it can be hard to encourage and enforce safe behaviors on the road. The good news is that modern technology can enhance these best practices and greatly reduce the risk of adverse incidents occurring on the road.

Modern technology provides operators with real-time information on the road. For example, operators can see rapid accelerations, abrupt braking or other safety-related incidents for each driver and either reward good behaviors or punish bad behaviors. Modern ELD systems can also help enforce Hours-of-Service guidelines for truckers and ensure they’re not in violation.

Powerfleet’s LV-9000 – Source: Powerfleet

The same technologies can help ensure proper maintenance and avoid equipment malfunctions that lead to accidents. For example, Powerfleet’s LV-9000 reduces compliance issues for drivers and constantly tracks working fleet engine hours, and using maintenance modules, plans ahead for PMs and avoids failures on the road that can lead to safety incidents.

In addition to avoiding problems, documentation is key to defending a business if something does occur. Accurate and up-to-date training records, logbooks and other documentation can help defend against claims of negligence while proactive measures to address safety concerns can go a long way in showing juries that the business takes safety seriously.

The Bottom Line

Nuclear verdicts have become increasingly commonplace in the trucking industry. While tort reforms could take years, trucking companies can protect their drivers and business from liability by investing in modern technologies and ensuring proper training and documentation measures are taken—minimizing the odds of both an incident and liability if one occurs.

Powerfleet for Logistics provides a range of hardware and software solutions designed to enhance on-the-road safety and minimize accidents, including an ELD-compliant solution that monitors driver behavior and enforced HoS and other regulations.