Background

ReedTMS Logistics (www.reedtms.com) is a family-owned, third-party logistics provider (3PL). The company delivers a broad range of 24/7 services, including:

- Brokerage

- Transportation

- Freight management

- Dedicated services

- Asset-based services

ReedTMS has quadrupled in size since its founding over 20 years ago. It now operates a private fleet of 85 trucks and 400 dry vans, tankers, and other trailers. With these assets, ReedTMS handles close to 100,000 shipments a year, serving hundreds of customers across a variety of industries

“Powerfleet’s solutions gave us the tools we needed to run the most efficient—and profitable—trailer fleet.”

Chad Walz

VP Operations,

ReedTMS Logistics

The Challenge

Like all carriers, ReedTMS wanted to move more loads to increase revenue and profits. At the same time, the company wanted to control expenses and cut unnecessary costs.

A fixed asset base of tractors, trailers, and infrastructure means fixed costs. If you can ship more freight with those assets, while managing costs, naturally you’ll earn more revenue-dollars per cost-dollar. And that, of course, equals higher profits.

ReedTMS decided that the smartest way to ship more loads, cut costs, and boost profits would be to increase asset utilization. Specifically, the company wanted to:

- Optimize trailer pool size

- Maximize driver efficiency

- Minimize empty trailers

With 80% of its business from dedicated or semi-private fleets, ReedTMS uses trailer pools to deliver the highest level of customer service. If it could reduce the size of those pools, without affecting service, it could reduce costs. And if ReedTMS could help its customers process trailers more quickly, it could maximize the capacity of those pools. Either way, the improved asset utilization would increase profit margins.

Trailer pools are also key to make the most efficient use of drivers’ time. ReedTMS wanted to operate its fleet 20-24 hours a day by effectively managing short hauls, with a high trailer-to-truck ratio. Short hauls could keep the assets moving, without exceeding any driver’s daily ELD limit of 14 hours. As an added bonus, this approach would make drivers happier, by letting them get home at the end of each day.

One downside of trailer pools is that empty trailers can dwell at a site for too long. This impacts both costs and revenue. For example, one ReedTMS customer received four loads in for every one load out, leaving many empty trailers to manage. As a result, drivers sometimes weren’t sure which trailers were empty, or where they were located. This could cause drivers to waste time searching for empties—and hit their 14-hour ELD limit. Without a backhaul, those drivers had to stay overnight and pay for a hotel. On top of that, the idle, empty trailers lost an opportunity to generate more revenue.

The Solution

ReedTMS started monitoring trailer locations with a basic Track and Trace solution from PowerFleet. This was perfect for locating missing trailers, and it quickly generated a positive return on investment (ROI). (See details under “The Results,” below.)

But to achieve the highest level of efficiency—to proactively manage trailer pools, drivers, and empties in real time—ReedTMS decided it needed an even more capable solution. So it turned to PowerFleet’s Dry Van Trailer Tracking system.

This system lets you know exactly where and when a trailer starts and stops, how long it dwells, and whether it’s loaded or empty. What ReedTMS liked most about the system was its:

- Easy installation

- Extended battery life

- Real-time location tracking

- GPS-based mileage reporting

- Sensors for full-trailer cargo detection, with time stamps for start and end of loading

Implementation

To install its new trailer tracking technology, ReedTMS needed to make the most efficient use of time, so it could keep fleet utilization high. To achieve this, the company used a two-prong approach.

First, ReedTMS ordered any new trailers it needed with the Dry Van Tracking System pre-installed. PowerFleet worked directly with the trailer OEMs to make this process smooth and reliable.

Second, for its existing trailers, ReedTMS installed Dry Van Tracking devices during normal planned maintenance (PMs). Fortunately, at most, the devices take only 60-90 minutes to install. So mounting them didn’t overload resources or delay the trailers from getting back on the road.

As an added level of support, PowerFleet integrated its web-based Powerfleet IQ™ asset tracking software with the McLeod software that ReedTMS already used for dispatching. As a result, ReedTMS could see—in real time—trailer distance from landmarks, dwell times of idle trailers, “dropped balls” in the dispatch process, and much more. Ultimately, these combined systems will proactively match dispatch orders with live trailer locations, which will prevent dispatch errors from occurring in the first place.

In addition, PowerFleet introduced ReedTMS to its Powerfleet IQ™ Analytics platform. This “big data” application crunches numbers from multiple sources to uncover deeper insights into operations. For example, ReedTMS plans to use FleetView IQ to integrate its trailer tracking and dispatch systems with ELOG, GPS, ELD and engine data from its tractor management system.

“From finding lost trailers and right-sizing our trailer pools to reducing new trailer buys, our tracking system has added over $1 million to our bottom line.”

Chad Walz

VP Operations,

ReedTMS Logistics

Results

Initially, the value of trailer tracking for ReedTMS was simply in finding trailers. For example, one customer would share trailers with different carriers, which sometimes resulted in a misplaced unit. Tracking the location of these “lost” trailers enabled ReedTMS to recover them easily. That alone saved the company hundreds of thousands of dollars in capital costs. Not to mention the cost of man-hours (and aggravation) it would have spent filing insurance claims.

But by switching to the Dry Van Trailer Tracking system—with its advanced cargo and load sensing, as well as “live” trailer location tracking—ReedTMS has been able to do (and save) much more:

- Find empty trailers in real time. This is especially critical at the end of the week, when customers need empties to load.

- Locate specific assets near customer locations without drivers searching for them. This reduces both the hard and soft costs of driver and trailer down-time.

- Improve fleet utilization. ReedTMS has achieved a trailer-to-truck ratio as high as 3.75 to 1, with minimal idle trailers.

- Direct decisions on new trailer buys/rentals. By right-sizing its trailer pools, ReedTMS has avoided over $1 million in capital costs. And generated more revenue per trailer.

The Powerfleet IQ software report that ReedTMS uses the most is an “Idle Trailer Summary.” It shows how long a trailer has been sitting still. Focusing on this data has helped ReedTMS reduce dwell time significantly. Management believes it can cut the average down to as little as 5 days.

ReedTMS uses this data to proactively manage customers and increase asset utilization. For example, if a loaded trailer remains at a customer site too long, ReedTMS will ask the customer to prioritize shipment, or charge the customer a storage fee. On the other hand, if a trailer in a customer’s dedicated pool sits empty on a regular basis, ReedTMS will pull the asset to use elsewhere and charge the customer less for the smaller pool.

Conclusion

By using advanced asset tracking technology, ReedTMS has been able to proactively manage its trailer pools, drivers, and empties—and improve dispatch efficiency. This visibility and control has helped the company increase asset utilization, reduce costs, and achieve its goals for revenue-per-asset.

ReedTMS now spends much less time waiting to pick up loaded trailers, unload trailers after delivery, and put empty trailers back into service.

“The key to our business is asset allocation and utilization, and I.D. Systems’ Logistics Visibility Solutions gave us the tools we needed to run the most efficient—and profitable—trailer fleet,” said Chad Walz, Vice President of Operations for ReedTMS Logistics. “From finding lost trailers and right-sizing our trailer pools to reducing new trailer buys, our tracking system has added over $1 million to our bottom line.”

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.

Let us help transform your business.

Challenge: In a Hyper-competitive Market, Do More with What You Have to Cut Costs

Five years ago, a leading multinational food & beverage company deployed Powerfleet’s® forklift telematics system to improve material handling safety. The project was a big success. Based on its initial return on investment (ROI), the Company rolled out Powerfleet on more than 2,500 pieces of material handling equipment across almost 100 of its food and beverage manufacturing and distribution sites in North America.

But with more than $60 million invested in its material handling fleet—and a labor cost of over $200 million to run that fleet—the Customer wanted to find out if Powerfleet could save it even more money.

Center of Excellence Looks to Expand Use of Powerfleet

This Company has a long history of using cutting-edge supply chain technology. For example, it is a leader in blockchain technology for sharing data securely across the food supply chain to help ensure food safety. The Company’s Center of Excellence (CoE) focuses on continuous improvement in manufacturing and distribution, with data as its life blood.

To find new ways to reduce material handling costs, one of the key data sets the CoE wanted to understand better was the relationship between lift truck safety and productivity.

With Powerfleet forklift telematics already in place across the Company’s entire fleet of lift trucks, the CoE didn’t have to look far to find the data-driven solution it needed.

Solution: Powerfleet IQ™ Forklift Analytics

To gain deeper insight into the cost of lift truck safety vs. operator efficiency vs. material handling velocity, the Company licensed Powerfleet IQ Analytics, a Powerfleet software option, to link data from multiple sources.

Specifically, the Company wanted to use Powerfleet IQ to blend these data ingredients:

- Number of damage-causing impacts recorded by forklift operators

- Time forklift operators spent actively working

- Number of pallets moved by lift truck operators

Key Considerations

Before launching a new technology for its material handling workforce, the Company knew from experience it needed to plan carefully and be proactive about the way it would use the data.

One of the pitfalls of data-driven technology, like Powerfleet IQ Analytics, is that the data can be overwhelming. Another challenge is translating the data into action. All too often, a flood of data is received passively, without a clear vision of what to look for or how to react.

For any new system to succeed, the people who will get the data need to know ahead of time what they will be looking for—and exactly what they are supposed to do with it.

A Carrot and Stick Plan

The Company knew that for Powerfleet IQ to be most effective, key employees—lift truck operators, line supervisors, facility managers, and corporate management—needed to care about the outcome. The Company had to make more than a financial investment; it had to engage and motivate these stakeholders.

The key to making workers care is accountability. So the Company devised a “carrot-and-stick” plan with both incentives for “good” behaviors and consequences for “bad” behaviors. Using Powerfleet IQ Analytics data, the Company:

- Developed a consistent set of metrics for material handling productivity and safety, regardless of the type and size of a facility, or the makeup of a site’s lift truck fleet.

- Established new benchmarks for pallet moves vs. lift truck motion time and impact events.

- Set up key performance indicator (KPI) scorecards for drivers, supervisors, and warehouse managers.

- Awarded cash bonuses and other incentives for meeting target KPIs.

- Retrained or reassigned forklift operators who failed to meet the benchmarks for safe productivity.

Results: Deep Data Insights Cut Forklift Damage 85% while Meeting/Exceeding Pallet-Move Goals

To better measure what sites and people needed a better balance of material handling productivity and safety, Powerfleet worked closely with the Company to integrate its Kronos® time-card system and SAP® warehouse management system (WMS) with Powerfleet IQ Forklift Analytics. This created a whole new set of integrated data points, such as:

- Lift truck operator paid-time vs. seat-time, deadhead-time, and time-in-motion-with-load

- Lift truck impacts vs. number of pallets moved

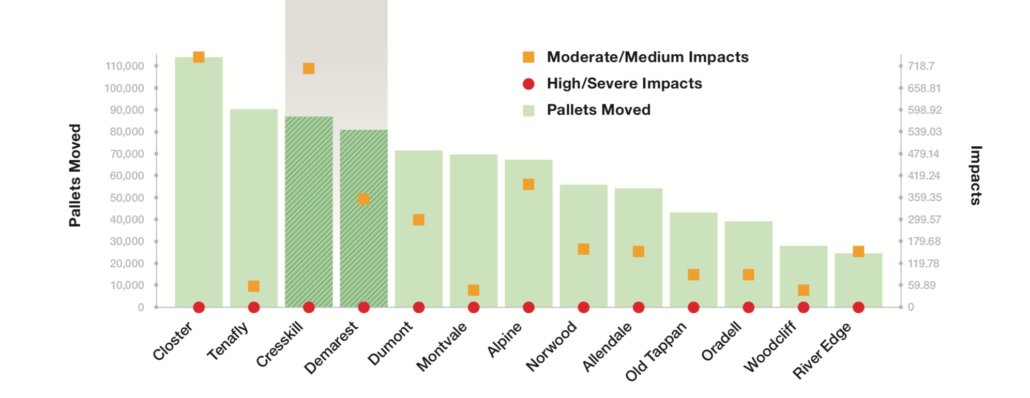

An excerpt of the latter type of chart is shown below, with the data aggregated by site. In this example, the “Demarest” site moves almost as many pallets as “Cresskill,” but with about half as many moderate and medium impact events. The user can click on any site to drill down into individual driver performance at that site, to determine which operators were at the root of the data.

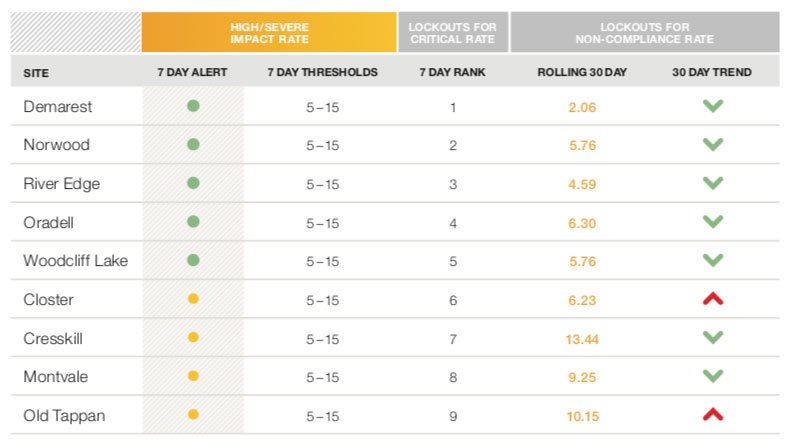

Powerfleet and the Customer also built KPI scorecards, so all the critical metrics could be digested in one quick bite. The following examples focus on, respectively, forklift fleet safety and productivity, by site. In the KPI scorecard excerpted below, the screen shows the 7-day safety rankings and 30-day trends of each site, based on their forklift fleets’ rate of high and severe impacts. Green dots indicate compliance with corporate standards; yellow dots suggest improvement is needed. (Red dots would indicate a site’s performance is unacceptable.)

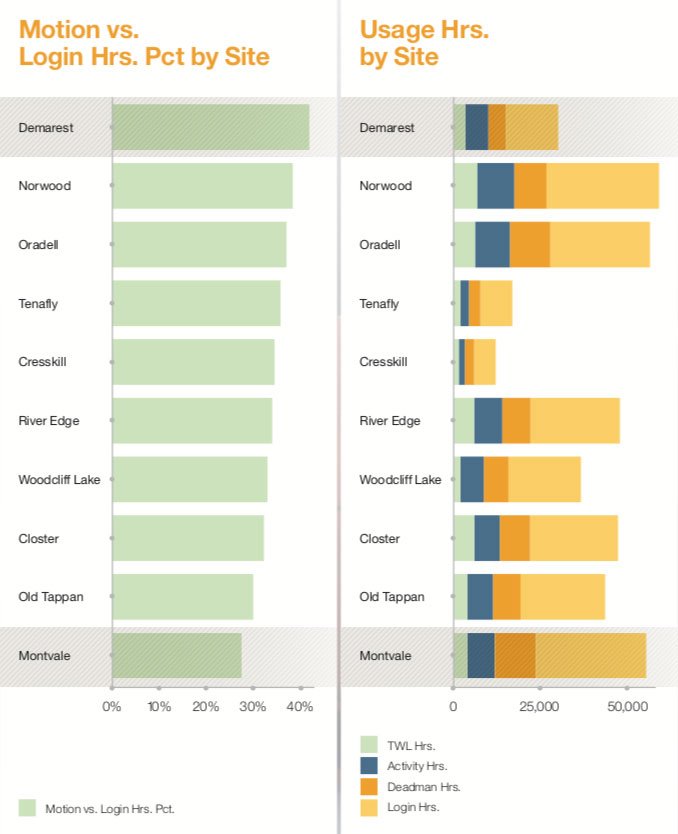

The next KPI scorecard excerpt ranks sites by forklift fleet efficiency, based on the amount of time vehicles spend in motion compared to the time vehicle operators are logged into the equipment. The “Demarest” site makes the most efficient use of its equipment—it has the highest ratio of motion (time vehicles are moving) to login (time drivers are logged in)—even though the site is average in its total hours of equipment usage. Conversely, although “Montvale” seems to be among the busiest sites, in terms of total hours of equipment usage, it is actually the lowest-performing in its ratio of vehicle motion time to driver login time.

“Powerfleet IQ Analytics drove much safer lift truck operations without a loss of material velocity: 85% less forklift damage and 100% of target pallet moves … for over $2 million in cost savings across the enterprise.”

Process for Validation and Action

The first key role of Powerfleet IQ was to validate data accuracy. One KPI scorecard monitored the health of system components—particularly to confirm that the Powerfleet vehicle-mounted hardware was collecting data normally and attributing it to identified operators. With validated data flowing smoothly, the Company went through a period of analysis over several months, without acting on the data. This enabled the Company to set expected benchmarks without rushing to judgment about individual operator performance. Importantly, the established benchmarks were ratios (not absolute numbers) to normalize performance across operators, vehicle types, and sites with different operating patterns.

The most critical benchmark ratios were:

- Pallets moved to severe forklift impacts (which have a high correlation to damage) and to medium forklift impacts (an indicator of excess wear and tear over time)

- Vehicle motion time to operator login time to Kronos® shift time

Also significantly, Powerfleet IQ enabled different standards to be set for different vehicle types, and accounted for drivers who operated different types of vehicles in same shift or day.

Based on these benchmark ratios, the Company set up multiple KPI scorecards for different stakeholders: individual drivers (with daily, weekly, and monthly metrics); supervisors (focused on all drivers each shift); warehouse managers (with a view of the entire facility); and corporate management (with stack-ranking of all sites in a single view).

This data hierarchy enabled a rapid, logical flow of information and decisions. Corporate management identified high- and low-performing sites. Facility managers saw where they ranked compared to other sites, and where they stood in relation to the target benchmarks. Line supervisors drilled down to understand which forklift operators were high achievers—and which needed refresher training. And forklift operators could see in black-and-white where they stood.

In the end, the food & beverage Company was able to drive much safer lift truck operations while maintaining high material velocity through its distribution system. The result was an 85% reduction in forklift damage costs with 100% achievement of target pallet moves.

Why Did Powerfleet IQ Analytics work so well?

“We worked with Powerfleet to integrate data from several systems and set up new benchmarks for safety and productivity. We validated the data, then analyzed it to identify specific opportunities to improve. By focusing on the sites and people that needed the most improvement, we were able to reduce forklift damage costs 85% while maintaining—or exceeding—our goals for pallet moves.”

— National Warehouse Manager

That damage reduction equated to well over $2 million in cost savings across the Company’s enterprise.

Conclusion: New Ways of Combining and Analyzing Lift Truck Data Can Radically Improve Material Handling Operations

Using Powerfleet IQ forklift analytics, this food and beverage Company was able to change the way it measured and balanced productivity (pallets moved) with safety (forklift collisions) and efficiency (active time on equipment vs. paid time). This data enabled a new approach to material handling discipline, with high-performers rewarded with financial and other incentives, and low-performers trained to improve. The bottom line was a stronger safety culture, with a new way to measure and manage productivity.

- Compliance with key safety metrics increased to essentially 100%

- Accidents and damage decreased more than 85%, while pallet moves remained at target levels

- Company-wide, Powerfleet IQ Forklift Analytics helped add more than $2 million in cost savings to the bottom line

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.

Let us help transform your business.

“Walmart’s choice was an application-specific wireless system from Powerfleet.”

Walmart Executive

Walmart Stores, Inc. is the world’s largest retailer, with nearly 6,200 stores and wholesale clubs across 26 countries, more than 800,000 associates worldwide, and revenue of more than $486 billion in fiscal 2014. The company has been termed “most admired retailer” by FORTUNE magazine.

Walmart also enjoys a reputation as a leader in supply chain technology and efficiency. It invented the practice of sharing sales data via computer networks with major suppliers and has been a global innovator in the use of wireless technology – warehouse management systems (WMS) and radio frequency (RF) data communication systems, for example – to track and manage the flow of goods though its distribution centers.

Never satisfied with the status quo when it comes to improving operations, Walmart began looking at wireless technology for another application: controlling and monitoring forklifts and industrial vehicles that move merchandise inside its distribution centers. More than 100 such vehicles are utilized in a typical Walmart distribution facility.

System Requirements

Walmart developed a list of required and desired functions for the “ideal” industrial vehicle management system.

For productivity management, Walmart wanted to implement new activity metrics to better analyze and optimize the utilization of vehicles and operators. Management also wished to achieve better asset visibility, including a more detailed understanding of time- motion history. In addition, Walmart wanted to enhance work assignment communication, especially in response to unexpected changes in task priorities.

Intelligent Control

What behavior do you want to manage, and what reaction to that behavior would you like?

For safety management, Walmart wanted to establish reliable vehicle access control, to ensure only properly trained operators could use equipment. A more easily managed method of completing, recording and archiving vehicle inspection checklists was also required. Impact sensing was also on the wish list, to increase visibility of unsafe driving and reduce accidental damage costs. Finally, Walmart wanted to consider how a fleet management system might influence maintenance efficiencies (for planning and executing preventive maintenance schedules, identifying emerging vehicle problems earlier, and establishing a better way to lock-out/tag-out equipment in need of maintenance).

Picking the Right Wireless Technology

Because industrial vehicles are mobile, they are inherently difficult to track, especially in a large distribution center (where they can easily “disappear” among rows of tall, merchandise-filled storage racks). It was obvious to Walmart that an automated wireless technology was needed to manage its many mobile industrial vehicles.

Walmart conducted an extensive review of available wireless vehicle tracking solutions, including those that could use Walmart’s existing wireless local network (2.4 GHz), those that used a cellular- based subscription service (like GPRS), and those that used a standard RFID spectrum (900 MHz).

Using the existing wireless network seemed logical and convenient on the surface, but it would have required every vehicle-mounted device to have its own network IP address, which has significant cost and labor implications for technical support and network upgrades. Furthermore, it was deemed desirable to keep vehicle management data signals segregated from the data transmissions of mission critical applications, like the WMS.

For wireless systems using cellular-based services, the main problem was ongoing cost – a per-asset, per-month payment that never ends (and that rises if data transmissions exceed a minimum level).

Such systems also rely on GPS receivers for asset location, which do not work indoors, where GPS signals are blocked by the roof of the building. Although cellular-based systems are common for over-the-road vehicle tracking, they are unsuitable for tracking vehicles in and around a distribution facility, where localized, no-cost RF communications are possible.

Ultimately, Walmart’s choice was an application specific wireless system from Powerfleet that uses the same unlicensed, cost-free 900 MHz radio frequency spectrum utilized by the RFID systems widely deployed in Walmart’s supply chain.

Picking the Right Vendor

Powerfleet is a leader in wireless asset management solutions, with a robust, technically advanced system specifically designed to manage fleets of industrial vehicles. Technical innovation, however, is not enough when it comes to deploying a wireless vehicle information technology at the world’s leading retailer. Just as important: experience installing hardware on a wide range of vehicle types; system configurability and flexibility; quality and user-friendliness; implementation and post-implementation support capabilities; and, perhaps most of all, demonstrated success partnering with customers to produce a solid bottom-line return on investment.

Powerfleet, a NASDAQ-listed public company, has the experience, financial strength, and human resources – including extensive engineering, training, and field support teams – to configure, deploy, support, and sustain its systems effectively across large- scale enterprises as well as individual facilities. In addition, Powerfleet helps customers generate a significant return on investment through a process of close, proactive engagement known as AdvantageTM support service.

The Solution

Walmart deployed its first wireless Vehicle Management System (VMS) from Powerfleet in a single facility as a pilot program to measure system benefits. After an extensive evaluation, the VMS was expanded across multiple distribution facilities. “The VMS delivered not only the promised safety and control benefits, but also significant incremental productivity improvements, above and beyond what our WMS was providing,” explained one Walmart supply chain executive.

As a productivity system, the VMS provided:

- Unique data on peak vehicle utilization that enables optimal fleet “right-sizing.”

- Unique metrics on operator activities that identify opportunities for productivity improvement and help optimize labor allocation across periods of varying activity levels.

- Software that displays a graphical facility map, which enables not only near real-time visibility of vehicle/operator location and status, but also the ability to play back a “breadcrumb trail” of vehicle movement over any slice of time.

- A two-way text messaging system that enables management to divert material handling resources effectively to the point of activity where they are needed

the most.

For safety management, the VMS provided:

- Electronic vehicle access control with an independent, on-board database of driver training authorizations, which establishes and maintains operator accountability whether or not the vehicle has a live communication link to the rest of the system.

- An electronic safety checklist system with a patented, hierarchical, question- and-answer architecture, which can be configured independently for any number of different vehicle types, and which lets management choose a variety of both on-vehicle and system-wide responses to vehicle problems.

- Impact sensing that provides a broad choice of automated management responses, from alerting a supervisor with visual or audible alarms, to generating a warning icon on a graphical software display of the facility, to sending an email or text page to management.

- Automatic reporting and prioritization of emerging repair issues identified

on electronic safety checklists, where operator responses are flagged by severity of vehicle condition. - Wireless remote lock-out/tag-out of equipment that is unsafe or in need of repair.

The Return on Investment

Together, these tools have provided Walmart (1) new ways to drive continuous improvement in material handling operations for increased productivity

and throughput and (2) new process controls for safety management. Just as important, the VMS has proved easy to use for the many Walmart stakeholders who interface with the system – vehicle operators, facility line management, information technology staff, and corporate management alike. In addition, from a technical operating perspective, the system’s wireless communication system has worked effectively alongside other wireless systems and processes, including Walmart’s extensive WMS and RFID systems.

“While we will not divulge the exact return on our investment in the VMS,” said the Walmart supply chain executive, “suffice to say we have found it well worthwhile to invest further in this technology.”

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.

Let us help transform your business.

Xerox Corporation, is the world’s leading document management, technology and services enterprise, providing the industry’s broadest portfolio of color and black-and-white document processing systems and related supplies, as well as document management consulting and outsourcing services. (NYSE: XRX)

The Xerox Corporation operates over 100 distribution centers; this study focuses on their Groveport, Ohio DC. This facility throughout supplies over 70% of the Xerox equipment shipped through the country. The Groveport DC is just under 500,000 sq. ft. and utilizes a mix of industrial vehicles, including reach trucks, counterbalance trucks and an order picker.

The Xerox team, led by Warehouse Manager Jerome Osborne, identified several key benefits a VMS would provide his operation, inlcuding: automated, electronic vehicle checklists for OSHA compliance; obtaining data… different areas; improving the overall…vehicle fleet.

Xerox, in partnership with Yale’s Hy-Tek Material Handling, evaluated several systems and ultimately chose the Powerfleet® Vehicle Management System (VMS) from I.D. Systems.

Safety First

One of Xerox’s key principles is “We value our employees,” so continually monitoring and investing in thesafety of their employees and DC is a top priority.

Access Control

Xerox wanted to ensure that each type of vehicle was only operated by a trained driver, a situation Xerox had found difficult to control. With Powerfleet, the site now only grants drivers access to vehicles they are trained to operate.

For instance, if an operator is not trained, or has an accident and needs to be re-certified, Mr. Osborne can easily restrict that operator from driving via the software, until certification is complete. Authorizing vehicle access for a new hire is just as easy.

Automated Vehicle Checklists

As with most companies, Xerox had manual, paper-based vehicle safety checklists that had to be completed for each vehicle daily. While this process followed their safety procedures, the paper-based process required valuable management time to monitor.

As with most companies, Xerox had manual, paper-based vehicle safety checklists that had to be completed for each vehicle daily. While this process followed their safety procedures, the paper-based process required valuable management time to monitor.

Operator compliance was often impossible to verify, and when issues were identified on checklists they could often not be rectified in a timely manner. Also, an extensive archive of the completed checklists was necessary to maintain OSHA-required history. Xerox had 3-4 years of paper checklists stored on-site using valuable storage space.

The on-vehicle Powerfleet device prompts each operator to complete a checklist; failure to do so disables that vehicle. This not only increases operator accountability, but also alerts management if operators are not completing the process. Since the checklist results are captured and stored electronically, Mr. Osborne can now review the checklist answers and operator compliance through an easy, automated report from his desktop.

Also, if a vehicle problem is identified on any checklist, he can simply lock out the vehicle from Powerfleet’s VisionTM software, instead of having to walk the floor, find the vehicle, and then lock it out physically. After deploying Powerfleet, the DC now can ensure that they have 100% compliance for their pre-shift checklist, completion.

After deploying Powerfleet, the DC now ensures 100% checklist completion.

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.

Let us help transform your business.

This case study focuses on Continental Tire’s Mt. Vernon, IL, manufacturing plant and warehouse for passenger, light truck and commercial tires. This facility manages the complete tire development process, from design to production to delivery. The Mt. Vernon manufacturing facility is one of the largest within Continental, with approximately 70 acres under one roof.

The Continental Tire team, led by Fleet & Rolling Stock Manager Nathan Baugher, identified several challenges that could be resolved with a Vehicle Management System (VMS). Initially, Continental Tire management wanted to reduce the abuse and damage associated with industrial vehicles within their facility. But after seeing the different capabilities that Powerfleet’s system had to offer, they realized the system’s potential to improve safety, productivity, and efficiency as well.

Consequently, Continental Tire chose the Powerfleet VMS from Powerfleet.

Safety Improvements

Industry-wide, industrial vehicle operators often use vehicles carelessly and managers are often not notified of unsafe conditions that may result, including facility, rack and inventory damage. Powerfleet solves that problem by establishing accountability for each and every vehicle. An operator must log in using Powerfleet to drive a vehicle. This ensures that only trained drivers can operate vehicles, and that each operator becomes responsible for the actions that follow.

Continental Tire has forecasted a 33% improvement in vehicle-related damage costs in just the warehouse alone.

“An increase in safety and awareness is definitely our number one priority,” said Mr. Baugher. “Near misses are just as bad as actual accidents. It is our goal to do everything in our power to create the safest working environment possible.” Since operators are now accountable for their vehicles with Powerfleet, there is heightened awareness and drivers are more careful of their surroundings. Continental Tire has forecasted a 33% improvement in vehicle-related damage in just the warehouse alone.

OSHA Safety Checklists

Continental Tire previously used paper checklists to complete their vehicle safety inspections. They had a common industry challenge where operators were not actively evaluating the vehicles and were blindly completing the form. Additionally, it took extensive administrative effort from the Production and Safety Departments to collect and manage the checklist paperwork.

Now, the on-vehicle Powerfleet device prompts each operator to complete a safety checklist prior to each shift or vehicle use; failure to do so can disable that vehicle. This not only increases operator accountability, but also alerts management if operators are not inspecting their vehicles. Since the checklist results are captured and stored electronically, Mr. Baugher and the safety team can now review checklist answers and operator compliance through an easy, automated report from their desktop.

In addition to increasing operator accountability, checklists have also increased vehicle maintenance efficiency. By looking at the answers the operators have given, maintenance can now quickly identify any issue with the vehicle and perform the needed work, before it becomes a major repair.

Fleet reduction goals were met within 4 months; within one year, the system will have paid for itself.

Fleet Reduction & Productivity

Without a vehicle management system, there is no way to consistently and accurately gather data on industrial vehicle use. With Powerfleet, the Continental Tire team captures comprehensive, detailed vehicle utilization data over time and makes fleet “right-sizing” decisions. They have also increased productivity by evaluating and benchmarking the activity of vehicles and personnel. “The data we are gathering is invaluable,” stated Mr. Baugher. “It’s like having an industrial engineer riding on every fork truck 24 hours a day, 7 days a week.”

By evaluating their vehicle use and productivity data, Continental Tire was able to eliminate a truck from their warehouse. In addition, they were able to reduce the headcount associated with the vehicle by eliminating three vacant staffing opportunities. This change alone resulted in over $100,000 in total savings. Mr. Baugher said, “the only reason we were able to make that change is because we could see the productivity data from Powerfleet. It’s challenging to remove vehicles from departments without data to prove that it won’t impact their day-to-day operations.”

Continental Tire has also increased industrial vehicle productivity by using the Powerfleet text messaging module. Managers in the warehouse send real-time text messages to operators dynamically as work requirements change – for example, if a fork truck is needed unexpectedly at a certain dock door. The operator can instantly answer back to confirm that the task is being completed. This change has virtually eliminated the need for 2-way radios in the warehousing facility.

Maintenance Benefits

Continental Tire deployed the Powerfleet Maintenance module to schedule preventive maintenance based on actual vehicle use, instead of on a calendar basis. Continental Tire’s maintenance is outsourced; when a vehicle is coming due for service, the module lets the service provider know, and the vehicle is scheduled accordingly. “It’s crucial to have a strong notification system in place to make sure we maintain our vehicle warranties,” noted Mr. Baugher.

To avoid work disruption, Powerfleet’s automated preventive maintenance notifications allow the service provider to pro actively plan the best day and time with a department to free up each vehicle. On the day of service, the service provider can use Powerfleet’s Vision software to instantly see the real-time location of the vehicle on a map of the facility. This means more time is spent servicing vehicles with less time spent searching

for them.

The Bottom Line

Mr. Baugher stated, “Our goal is to have a plantwide fleet management program based on utilization and hours, which would be impossible to achieve without data. Powerfleet offers the perfect solution because it tracks exactly the data we need and is one of the key building blocks to obtain our overall goal for the facility.”

Mr. Baugher continued, “We want to be the #1 tire manufacturing facility in the world and the plant of choice for the introduction of new products. Powerfleet helps drive process costs down and increases productivity, which ultimately lowers our cost per tire and positively impacts the bottom line.”

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.

Let us help transform your business.

“Since adding Powerfleet®, our business grew, our fleet grew, however, our need for trailers did not grow proportionately, due to the increased utilization that tracking helped provide.”

Tim Parker

Vice President of Service Operations

Forward Air

Increased Utilization

Forward Air Corporation is a leading provider of time- definite surface transportation and related logistics services to the North American air freight and expedited LTL market. In 2007, Forward Air began deploying the Powerfleet trailer tracking devices across its LTL trailer fleet, supporting deliveries through its central hub in Columbus, Ohio and 11 regional hubs to 85 cities across North America. Since implementation of the system began, Forward Air has grown its core business and added three new business groups.

Offering New Services

“Forward Air added new services such as intermodal drayage, pool distribution, expedited truck load operations, and a door-to-door offering- Forward Air Complete,” explains Tim Parker, Forward Air’s Vice President of Service Operations. “These new services required equipment to be placed at customer locations and to occasionally be pulled by non-FAF power units. The visibility and control of our equipment was significantly reduced. Adding Powerfleet Track-and-Trace improved visibility at every location.”

Improved Operations

After initially using Powerfleet to react to questions about how their trailers were being used, the company’s application of the system evolved with more active use, removing the need for manual yard checks. As a result, identification of misused assets became more efficient, and the manpower dedicated to daily monitoring of each site’s inventory was reduced.

Operations managers at each of Forward Air’s 85 local stations use Powerfleet to perform yard checks at their locations, as well as at customer yards that belong to their pool. The Powerfleet FleetView platform website dormancy reporting capabilities are then used to help identify excess trailers that can be eliminated from their pool.

In 2010, Forward Air began replacing their existing Powerfleet tracking devices with Powerfleet’s new Track-and-Trace product. Benefits of the low-cost device include the ability to ping for trailer location on demand, which is critical to locating stolen assets or other moving targets. With an up-to-date trailer position, drivers on trailer search missions can be routed directly for pick up, saving valuable hours of service and fuel costs dedicated to hunting for misplaced units. Maintenance budgets have also benefited from the addition of the new devices due to ease of installation and battery replacement, plus the assistance it provides maintenance managers in scheduling service.

After initially using Powerfleet to react to questions about how their trailers were being used, the company’s application of the system evolved with more active use, removing the need for manual yard checks. As a result, identification of misused assets became more efficient, and the manpower dedicated to daily monitoring of each site’s inventory was reduced.

Operations managers at each of Forward Air’s 85 local stations use Powerfleet to perform yard checks at their locations, as well as at customer yards that belong to their pool. The Powerfleet FleetView platform website dormancy reporting capabilities are then used to help identify excess trailers that can be eliminated from their pool.

In 2010, Forward Air began replacing their existing Powerfleet tracking devices with Powerfleet’s new Track-and-Trace product. Benefits of the low-cost device include the ability to ping for trailer location on demand, which is critical to locating stolen assets or other moving targets. With an up-to-date trailer position, drivers on trailer search missions can be routed directly for pick up, saving valuable hours of service and fuel costs dedicated to hunting for misplaced units. Maintenance budgets have also benefited from the addition of the new devices due to ease of installation and battery replacement, plus the assistance it provides maintenance managers in scheduling service.

Improved Customer Service

The benefits of Track-and-Trace have extended to Forward Air’s customers as well. Forward Air customers can access the VIP website to monitor the location and security of their loads.

“The quick set up and intuitive format of the VIP website has allowed us to extend the value of the product directly to our customers,” added Parker. “Our customers can log in to the website and view their specific information to help them better manage their equipment and utilization levels. We also rarely have to burden our customers with manual yard checks. Instead, the customers are empowered to quickly ascertain their equipment and utilization levels.”

Powerfleet has helped Forward Air improve their trailer fleet utilization by 15%, while also improving bottom line performance by an estimated $500,000 per year.

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.

Let us help transform your business.

“Without Powerfleet for Logistics solutions, the odds of recovering stolen goods are low. Word is likely to be out on the street that Knight is not a desired target given our tracking capabilities.”

Richard Martin

Corporate Director of Security,

Knight Transportation, Inc.

Theft Recovery No. 1

In Long Beach, CA, a Knight Transportation driver reported that his truck and trailer were missing. The security department immediately enabled Emergency Track on its Powerfleet for Logistics system to begin the trailer location process. It was discovered that the trailer traveled throughout the previous night ending its journey in Rialto, CA at 8:51 a.m. The authorities were notified of the stolen trailer and were told exactly where it was parked, based on the last location delivered by the Powerfleet system. Surveillancewas immediately established across from a large warehouse facility.

Mission Success– The missing trailer came out of the warehouse hooked to a different tractor. The rig was followed by police and the driver was arrested. The authorities recovered all 111 televisions valued at over $100,000, as well as the tractor. Interestingly, a container was also retrieved containing fabric worth over $250,000 that wasn’t yet reported stolen. Several more arrests were made at the scene.

Theft Recovery No. 2

A Knight Transportation tractor and trailer were reported missing during a particularly busy night in the middle of the peak holiday season. Using the VeriWise system’s reporting features, authorities were able to pinpoint the last known location of the trailer in Compton, CA. Upon arrival at the site, the tractor and trailer, minus the cargo, were recovered. Knight security personnel then back-tracked through the location history of the trailer provided by the system’s best-in-class user interface. It was discovered that the trailer had been parked for several hours the night before in Long Beach, CA at the site of a warehouse and storage facility.

Victorious Recovery – A search warrant was obtained for the warehouse where the authorities found the stolen load of electronics equipment valued at over $335,000. Two additional stolen loads were recovered as well. Over 200 televisions were recovered that were shipped from China and reported stolen. In addition, a load of cosmetics was also recovered and returned to its owners.

Estimated Recovered Value: Over $1 Million. Powerfleet not only improves the efficiency of managing Knight Transportation’s trailer fleet by increasing overall trailer utilization, it also provides a critical security benefit in greatly increasing the chances of recovering stolen cargo.

Powerfleet transforms the way organizations manage mobile business assets — like forklifts, cargo trailers, and connected cars. Our technologies control, track, analyze, and optimize hundreds of thousands of these assets all over the world. We help organizations be safer, improve efficiency, and cut costs.